Created on 2025.06.13

What are Checking Fixtures?

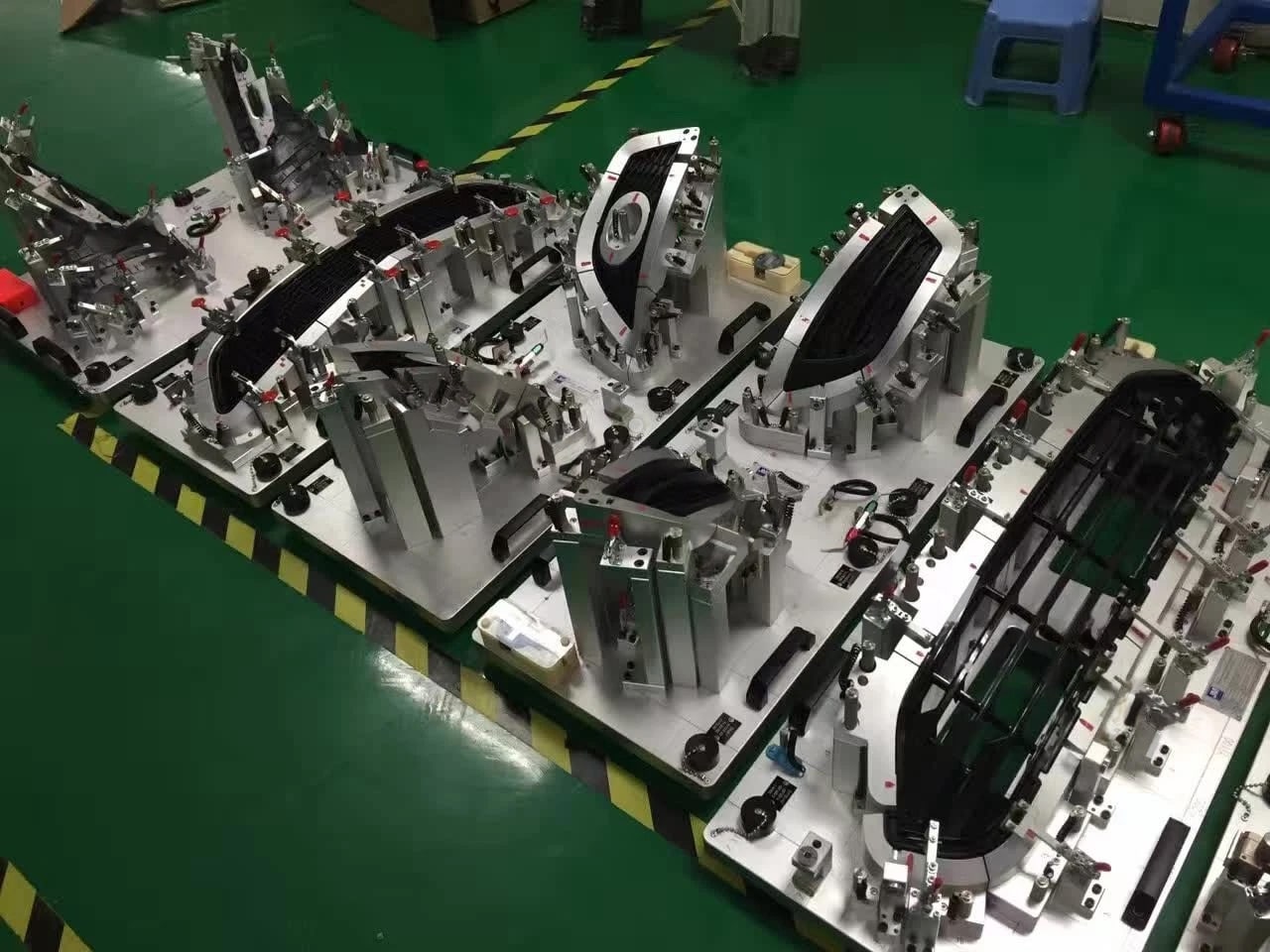

Checking fixtures are used in manufacturing to verify that products meet required dimensions, tolerances, and quality specifications. They serve as a point-of-reference when inspecting parts during production for accuracy.

Custom Checking fixturesare designed to serve as a comparison platform against which manufacturers can evaluate the workpieces they produce. By simulating final assembly conditions or matching parts, manufacturers are able to gauge whether each part falls within acceptable parameters and assess any discrepancies accordingly.

Checking fixtures are used primarily to detect errors and variations that arise during production, helping companies detect deviations early and reduce waste as well as costly reworks or customer complaints.

Checking fixtures take on various forms depending on their use and complexity, from simple features such as holes or slots that allow quick visual checks to intricate designs with multiple contact points for precise measurements.

Checking fixtures are integral in maintaining consistent quality control throughout manufacturing processes by offering accurate measurements and supporting efficient inspection processes.

Contact

Leave your information and we will contact you.